Choosing an appropriate material for the job can be tricky sometimes! Do you know what PTFE, FEP, PFA & ETFE are? These are all varieties of a kind of substance known as fluoropolymers. They have unique properties that contribute to various tasks. Below we are going to compare these materials and find out which one is right for you.

PTFE, FEP, PFA, and ETFEWhat is PTFE?

First, let’s understand what we are even talking about with these words. PTFE is polytetrafluoroethylene, FEP is fluorinated ethylene propylene, PFA is perfluoroalkoxy, and ETFE is ethylene tetrafluoroethylene. The material is a special kind of plastic so tough that it can withstand heat, chemicals and electricity.

Selecting the Best Fluoropolymer

When choosing a material, consider its job. PTFE is an excellent material for wire coatings, because it is slippery and can withstand high temperatures. FEP is great for tubing due to its clarity and bendability. Gaskets and seals: Tough and resistant to chemicals, PFA is commonly used. ETFE is ideal for film and sheet — it’s strong and able to withstand the sun.

Performance comparison of both the materials

All these materials have their own unique characteristics. PTFE is very slippery; it can be used as a lubricant and exhibit a fairly high melt temperature. FEP is flexible and clear so you can see through easily when inspection of the material is required. It is tough, resistant to chemicals, and good for tough jobs. ETFE is also strong and sun resistant, so it’s commonly put outdoors.

6.1 Resistance of Fluoropolymer Materials against Chemicals

In choosing a material, consider how well it can resist a range of chemicals. PTFE is appreciated for its resistance to acids and bases, which is why it is widely used in lab equipment. Although FEP isn’t as chemically resistant as PTFE, it can still withstand a wide variety of chemicals. PFA is even more chemical-resistant than FEP and thus is a good option for factories. ETFE is also incredibly resistant, particularly to acids and bases, and that's why it's what we use a lot of the times in construction.

Aspects to take into consideration when selecting a material

And when choosing what materials to bring, keep a few things in mind. Consider the temperature, the chemicals involved and how flexible the material must be. Think about how strong and sturdy it needs to be, and how it’s going to hold up in different locations. When you keep both these considerations in mind, you are on your way to select a suitable material for your requirement.

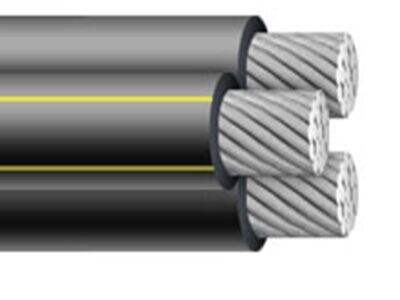

In summary, Medium Voltage Power Cable each of these types of fluoropolymers have different properties that make them good for different things. Whether you want something slippery, transparent, tough or strong, there’s a material that will do the job. It will depend on your requirements and what each material has as features. Just remember when it comes to get right material for your job, Huatong cable have all of them!