Huatong Cable would like to introduce you to two main types of cables: armored and unarmored! These cables are found in just about every place imaginable, from power plants where electricity is generated, to office buildings where we work day after day. There are pros and cons to both styles of cables. So, let’s get right into each type and learn more about what makes each special!

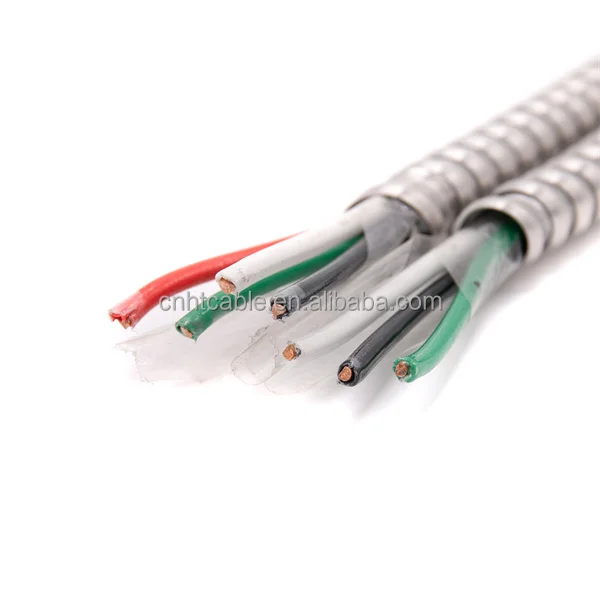

Unlike most electrical cable, armored cable has a solid metal wrap encasing it. So the cable is pretty tough and hard to break, thanks to the metal layer, which is very crucial in places where things get badly damaged. Unarmored cable, on the other hand, does not come with a metal coating. This makes it lighter and more flexible, enabling it to bend and twist easily in the necessary moments. For these reasons, armored cable is utilized in areas where there is a risk of damage, and unarmored cable is used in regular environments where it is less likely.

So, let’s discuss the positives of armored cable. This type of cable offers one of its best attributes: they are very difficult to break or wear out. That makes it ideal for harsh environments, including factories or outdoor areas where equipment might be hit, or scratched. But there is a downside to this as well. Because it is heavy, bulky, and tangled, armored cable can be cumbersome to install. This can lead to longer and more expensive installation costs.

Now let’s take a peek at unarmored cable. One of the best attributes of unarmored cable is that it is very light and easy to carry and workplace. It comes in especially handy for projects that need doing fast. The disadvantage, though, is that unarmored cable lacks the strength of armored campaign. Since it has no protective metal coating, it doesn't perform as well in exposing places where it can become damaged, which makes it unsuitable for rugged environments.

In places where the cable is likely to be damaged, the best option is armored cable. It is used in many industries and is best to use in the close expert environment where energy and large devices exist, e.g., in power plants. The metal layer protects the cable it covers to some degree from many dangers, including water, heat, chemicals, and so on, in addition to preventing electromagnetic interference. This is why armored cable is used in these instances to keep everything safe and functioning.

The unarmored cable insulated that allows its usage in different environments that helps make this cable very useful. It is present in office buildings where we work, homes where those families live, and outdoor applications. This makes it a fantastic option for flexible, easy install setups. For example, it is possible to use in cable trays and ducts, which are special paths for cables. Since unarmored cable tends to be cheaper, it is frequently built into and designed for many projects and installations as a result.

There are some key considerations when choosing between 10mm armored cable for your application. Find out what environment your cable needs to be installed in. If damage risks are great (as in a factory or outdoors), armored cable is typically the best option. Second, consider the distance the cable has to cover. Armoured cable is just too heavy and cumbersome if they are going to run a long distance. Finally, think about your budget. Armored cable can be more on the costly side than unarmored cable, so consider how much you can afford to spend on your project.

We armored and unarmored cable testing equipment, including AC spark testers, MV cable partial discharge equipment, Aging test chamber, Online Diameter Gauge, High low temperature a test chamber, Combustion for bunched cable experiment device, Partial discharge test device, Thermal elongation test device so on. chamber, Combustion for bunched cable experiment device, Partial discharge test device, Thermal elongation test device so on improve quality products available customers

Hebei Huatong Wires Cables Group Co., Ltd. was founded in 1993. The facility covers an area armored and unarmored cables squared meters and the annual sales volumes is 800W US dollars. Our main products are LVs Powers cables for MV up to 35kv, Rubber Our main products are LVs Powers cables for MV from 35kv to 35kv, Rubbers cables(Welding cables as well as Crane cables Mining cables, Silicon rubber cables), Submersible cable for pumping, Control cables, Instrument cables, Cables for shipyards, Elevator cables, Shipyard cables, and other cables. Elevator cables, Shipboard cables, solar cables, vehicle cables ABC cables, conductors.

armored and unarmored cable well-known loved many countries, including USA, Canada international markets such Holland, Italy Russia. export Australia, New Zealand Ethiopia.

Ours products are certified by ULs, CULs and armored and unarmored cables. We also holds ISO9001, ISO14001 and OHSAS18001 certifications. Ours UL certificates includes XHHW/THHN/SER/SEU/MWELDING/AC/MC CABLES/DLO/SJOOW. Our shipboards cables is approved in eights countries. China Japan South Korea USA Germany UK France.